piggyWelder® Welding at the highest level - Simple. Powerful. Fast.

Create connections that last – from delicate precision weld seams to repair welding of heavily stressed workpieces.

Advantages of welding with piggy® welding systems

Precise & controlled

Ideal for delicate components and repair welding

Durable & resilient

For the highest demands on seam quality

Efficient & versatile

Fast welding processes for a wide range of materials and applications

Let us advise you individually

Are you looking for the optimum welding solution for your application? Or do you have special requirements that go beyond standard solutions? We will advise you individually and help you select the right welding system and accessories for your requirements.

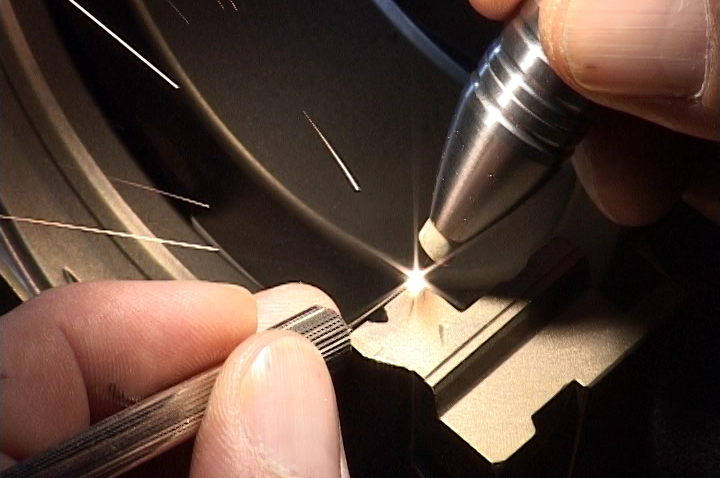

Our welding system at work

Would you like to take a look at the performance of our piggy® welding systems? Then visit our welding video page!

Watch examples of how we work from complex repair welding to filigree precision welding of the smallest components.

Discover the piggyWelder® in the store

Are you looking for the right welding machine for your application? You can find the piggyWelder in our online store for welding technology ® for a wide range of applications, materials and budgets.

Welding: reliable and precise

Whether edge, surface or web – with the piggy® welding systems you can react immediately and weld with the highest precision and outstanding quality, from repair welding in mold making to precision welding of the smallest components.

The piggyWelder® 4 enables precise spot welds in just 0.5 seconds thanks to micro TIG technology and is immediately ready for use thanks to pre-programmed settings for steel, copper and even aluminum – directly on the machine. Deformations and metal stresses are a thing of the past: all the heat is concentrated on the welding spot, which also increases the service life of the tool.

The carbide coating device Tucadur complements your options perfectly by making surfaces extremely wear-resistant – protecting your molds and tools from renewed wear in the long term. Ideal for the highest demands on durability and functionality.

A wide range of laser and TIG welding wireswhich are specially tailored to the requirements of tool and mold making, completes the range for functional welding with maximum hardness and wear resistance.

This is how welding with the piggy®Welder works:

1. preparation of the workpiece

Prepare the workpiece according to the materials to be welded and the desired seam type.

2. setting the system

Set the parameters on your piggyWelder system – depending on the material, material thickness and welding task (e.g. repair welding or precision welding).

3. start the welding process

Carry out the welding process with precision. The systems ensure stable arc guidance and uniform heat input.

4. inspection of the weld seam

Check the finished weld seam for quality and the desired appearance.

The piggy®Welder for your needs - contact us now!

Are you interested in one of our welding systems, but are unsure which solution is best for your specific requirements?

The piggy banks will be happy to help you personally – competently, quickly and without obligation.

Areas of application for our welding systems

Our piggyWelders are extremely versatile and are used in numerous areas – from industry to the trade through to specific specialized areas:

Welding systems in industry & mechanical engineering:

- Repair and maintenance of machine components and tools

- Production of complex metal constructions

- Joining sheet metal and profiles

- Precision welding in plant engineering

Welding systems in mold & tool making:

- Repair welding of molds, inserts and complex geometries to restore functionality

- Build-up welding for adapting and optimizing tools

- Connecting tool components with maximum precision

Martin Schriever

Tel.: 02204 – 30 66 12

ms@diesparschweine.de

Polishing and repair welding

If you have any questions regarding polishing or repair welding, pick up the phone and call our expert Martin Schriever. He has spent the past 30 years polishing just about everything in the tool and die business with various polishers. For 3 years he worked in Mexico as an independent contractor in the automotive maintenance sector.