Our catalogue

The savings program for mould and die makers

You will find everything you need for grinding, lapping, polishing and welding on 384 pages. Drives with ultrasound, powerful micromotors, motors with flexible shafts and an extensive range of pneumatic devices are available.

Order your piggy bank catalogue today, the savings program for mould and diemakers. A call to +49 02204 – 30 66 0 or an email to info@diesparschweine.de is sufficient. Or click on the following button for an order via our webshop:

And if you prefer to browse the catalogue digitally right away, click the button below:

Drives

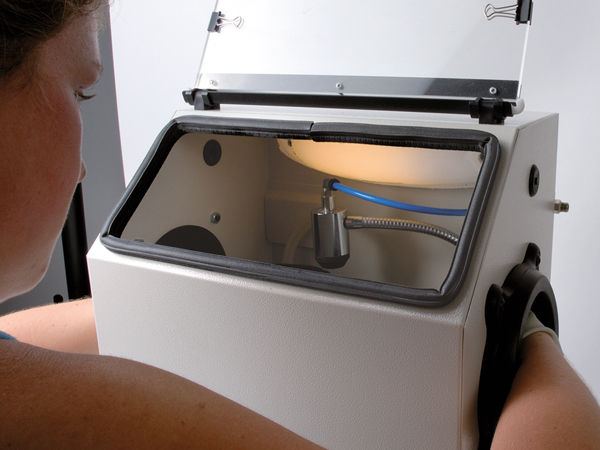

In this chapter you will find micromotors, ultrasonic polishing systems, flexible shafts, compressed air handpieces, as well as suitable control units, handpieces, suspended motors and accessories.

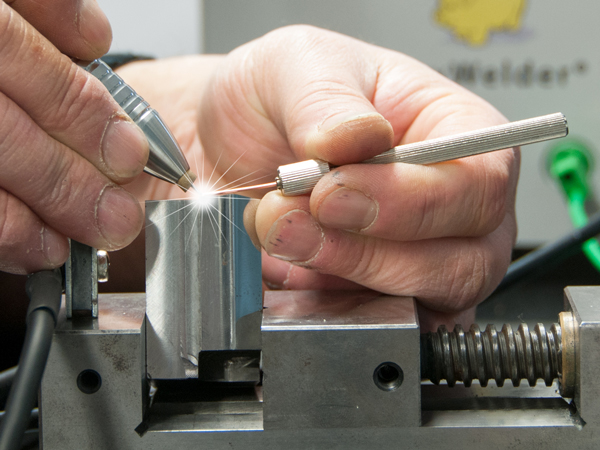

Welding

When it comes to repair welding on moulds without lasers, this chapter is for you. The welding section offers you everything that makes precision welding in your own workshop easy. Welding under shielding gas with the microscope and laser wires from 0.2 to 1.0 mm. This covers all normal tasks in mould making.

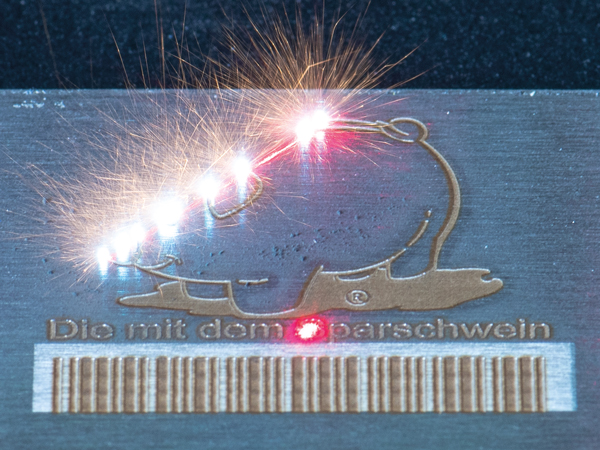

Laser marking

Laser marking looks professional and underlines the quality of your moulds and tools. Therefore we introduced the chapter "Marking". Here you will find laser markers for various tasks as well as suitable accessories.

Linear movement

In daily, most of the polishing process is made with tools for linear motion. This chapter mainly contains polishing stones, ceramic fiber files and brushes, grinding and diamond files and matching holders.

Polishing

In this chapter you will find everything you need for working from the initial surfaces up to high-gloss polishing, like Kemet® Diamond pastes, fluids, polishing-bodies, -woods, -felts, -tools, -brushes,

-paste and -cotton.

Milling

Our rotary carbide cutters are grounded from the solid. This results in a constant cutting angle of the spiral grouped gear. The use of carbide milling cutters imposes itself, where the very highest demands are made. Therefore, in this chapter you will find a wide selection of high-quality milling cutters.

Grinding

What characterizes grinding is the firm bonding of the grain (abrasive) in the tool or on a surface, e.g. grinding wheel or abrasive cloth. Therefore, in this chapter you will find sandpaper, sheets, cloth, cords and pins, as well as flap sanders, diamond foils and rubber-bonded tools.

Clean

A clean workpieces and workplace is an important point for successful work. For this purpose, you will find ultrasonic cleaning equipment with universal cleaner, spray cleaner, plastic cleaner, cleaning cloths and brushes in this chapter.

Coating

If you want to coat heavily stressed surfaces with tungsten carbide, quickly, easily and reliably, you will find the right equipment as well as the right accessories in this chapter.

Workplace

In this chapter you will find everything you need in addition to your tools and consumables at the workplace, such as clamping tables and balls, vises, silicone moulding compound, magnifying glasses, microscopes, lamps, lights, cold light sources, extractors, copper and soft hammers, gloves, protective equipment and hand cleaners.

Blasting

This surface treatment is carried out in our work field either for cleaning moulds or for even surface matting. Therefore in this chapter we offer you blasting equipment as well as suitable blasting media.

Repair

We have an excellent repair service. However, if you prefer to do it yourself, you will find suitable spare parts for flexible shafts and for many of our offered handpieces in this chapter.

Seminars

With our seminars we support you in the field of polishing with our knowledge and experience. If you want to benefit from it, you will find all the necessary information in this chapter.