Kemet® polishing machines Lapping in

Professional quality - Precise. Efficient. Mirror finish.

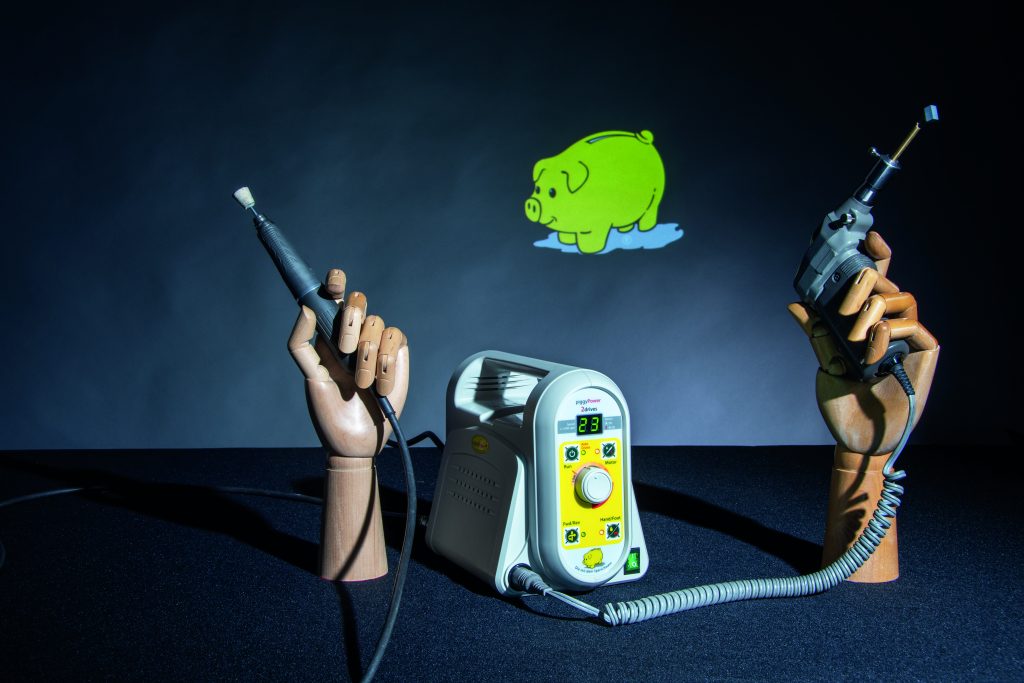

Achieve perfect, flat surfaces and a mirror-like shine with the robust Kemet® lapping and polishing systems – from the piggy banks for piggy banks.

Advantages of lapping with Kemet® systems

Highest precision

Ideal for processing and correcting concave surfaces.

Flawless results

For reflective surfaces, even with demanding materials.

Versatile in use

Flexible for a wide range of workpieces, including decorative surfaces.

Are you looking for the right machine for polishing and lapping? - Ask the piggy banks!

The Kemet® lapping machines and materials in use

There is enough talk about precision. We’d rather show you, What our lapping and polishing technology can really do. On our video page you can see the devices and materials in tough everyday workshop use – real practical examples of flat lapping and polishing.

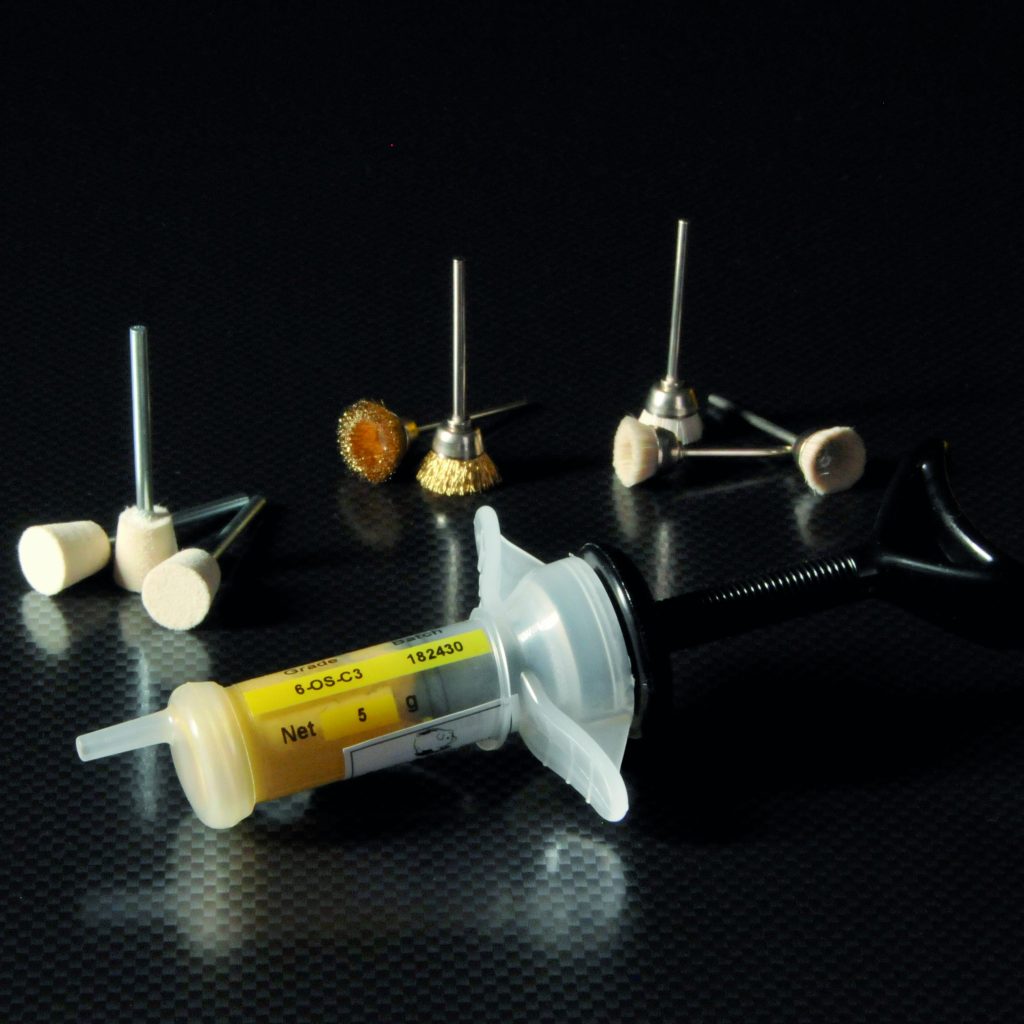

Everything for the perfect shine in our online store

In the Piggyshop you will find polishing pastes, molds and accessories – ideal for precise results and long-lasting surfaces. Order directly online and get started right away!

Lapping: Because every last micrometer counts.

You are probably familiar with this: A component is almost perfect, but the sealing surface does not close 100% or the fit has slight play. Precisely for these cases, in which maximum precision and flatness are required, lapping is the process of choice.

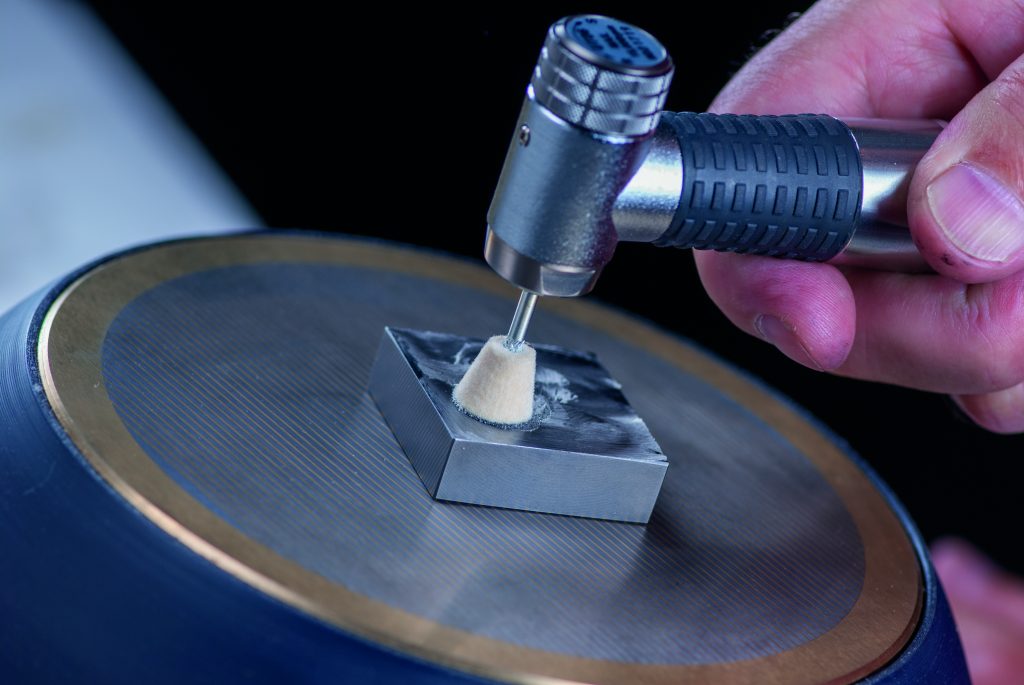

In this process, a loose abrasive grain – for example silicon carbide or aluminum oxide – is used in a liquid or paste to remove specific material. Our robust Kemet® polishing machines are made for this mechanical lapping. You reliably produce precisely flat surfaces on almost any material – from metal and ceramic to glass and plastic.

However, the Kemet® systems are not just pure lapping machines. Due to the simple Change from lapping wheel to polishing disk you can transform your device into a full-fledged polishing fully-fledged polishing machine. So you only need one system for two crucial work steps – saving space in the workshop and protecting your budget. This is what clever working with the piggy banks looks like!

Get comprehensive information about our flat lapping and polishing machines, their applications and technical advantages.

How easy it is to polish lapping with Kemet® products:

1. preparation & equipping

The cleaned workpiece is placed on the lapping disk set. Then enter the appropriate Lapping mixture (e.g. diamond paste or lapping oil).

2. the lapping process

The machine starts. The rotation of the disk causes the lapping grains to roll and slide between the workpiece and the disk. This process removes material extremely evenlyuntil the desired evenness and surface quality is achieved.

3. testing & further processing

Check the result and see a perfectly perfectly lapped surface. It is the ideal basis for a subsequent high-gloss polish.

Good advice pays off.

We are not interested in selling you just any machine. We want you to get the right and most economical solution for your workshop that pays off for you.

Talk to us before you invest. The piggy banks will help you make a decision that will benefit you in the future – that’s a promise.

Typical applications of our Kemet® lapping machines and media in industry and workshops

The following examples show where our customers are already using the high-quality Kemet® machines and lapping materials on a daily basis. in daily use in daily use.

Industry & mechanical engineering:

- Painting sealing surfaces on valves, pumps and housings

- Production of flat surfaces on gear parts and bearings

- Precision machining of calipers and gauge blocks

Mold & tool making:

- Creating perfect parting edges on injection molds

- Fine machining of cutting punches and dies for maximum tool life

Optics & precision mechanics:

- Processing of optical glass and crystals

- Manufacture of components for watches and measuring instruments

Martin Schriever

Tel.: 02204 – 30 66 12

ms@diesparschweine.de